The coronavirus disaster simply highlighted the significance of in-warehouse administration and on-line purchases delivered at residence. However, behind the superbly greased operations of an industrial facility or the effectivity that permits receiving a package deal at residence in a few days, quite a few applied sciences normally go unnoticed. Inventory administration, items receipt, and transport, or their monitoring till they attain our properties, often known as “last mile” supply, embrace an especially advanced vary of operations the place a single misstep can threaten the entire course of. Fortunately, globalization and the exponential development of products site visitors have witnessed the beginning of a brand new technology of logistics administration applied sciences: from robots that choose supplies at automotive factories or merchandise at business warehouses to self-driving platforms that carry heavy supplies forwards and backwards. The current and, particularly, the way forward for logistics are technology-driven.

All these revolutionary applied sciences, the place ACCIONA is enjoying an lively position, imply safer work environments, higher-quality manufacturing, and cost-efficient operations due to elevated productiveness.

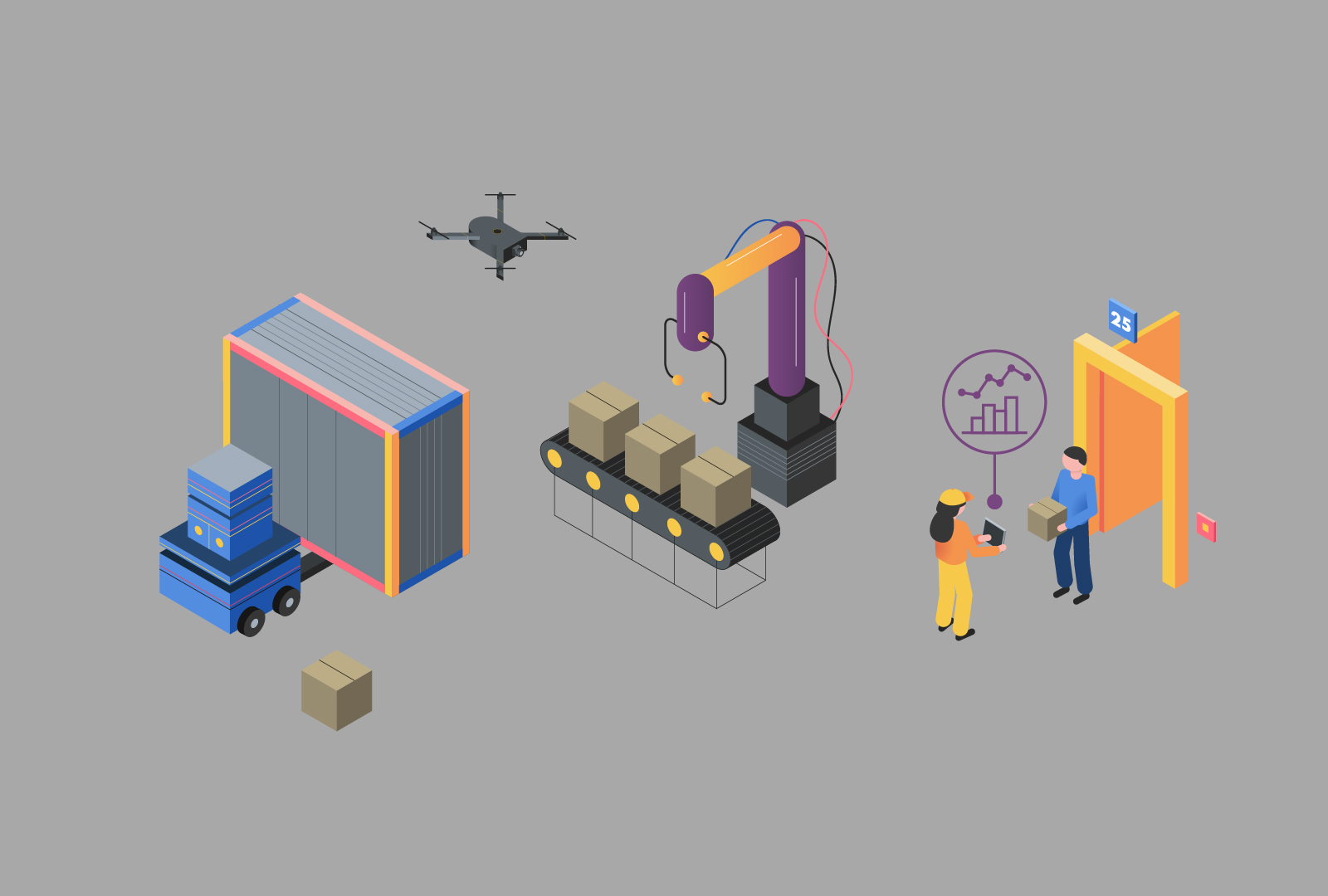

Stages of a sophisticated logistics operation

Stage 1: Receipt of products

-Robotic arms: execute essentially the most repetitive duties autonomously.

-Autonomous platforms: inside transport of supplies by tracing essentially the most environment friendly route.

Stage 2: Integral warehouse administration

-Drones: management stock and detect doable safety issues.

-Sensors: to ensure the well being of operators.

-Exoskeletons: restrict the bodily overexertion of staff and permit the lifting of heavier hundreds.

Stage 3: Distribution of products over lengthy distances

-Data evaluation: and GPS to optimize routes.

-IOT: product traceability.

-Blockchain: verification of course of components.

Stage 4: Last mile

-Order monitoring and ultimate buyer satisfaction.

-AI: algorithms for job project and planning of supply routes in actual time.

Robotics on the warehouse

Especially in heavy and automotive industries, shifting manufacturing supplies from one place to a different is a crucial and important course of. Over the previous couple of years, self-driving cellular platforms have change into more and more useful instruments. Thanks to their sensors and onboard cameras, these robotic techniques have collision detection capabilities and might discover the optimum transport route. GPS and information analytics techniques perform route optimization.

Another expertise within the processing of an order acquired at a facility is using collaborative robotic arms that select parts. While nonetheless in an experimental stage, they’ll show a beneficial assist for staff, liberating them from tedious and repetitive duties.

Finally, drones are one other autonomous system with an elevated presence at warehouses. They are used for monitoring inventory, stock administration, and surveillance within the services and tough entry areas.

Safety first

Regarding staff, exoskeletons are one of many techniques on the rise. Some of them are passive, i.e., they simply redistribute weights all through the physique or launch them as vitality to the bottom. There are, nevertheless, extra superior lively exoskeletons that characteristic sensors and actuators that may scale back the precise lifted weight. Some of these exoskeletons permit lifting as much as 200 kilos effortlessly. Nevertheless, any bodily exercise nonetheless has dangers of its personal. Thus, sensors that detect very important indicators are one of many options which might be being carried out. These techniques alert to any anomalies. Featuring GPS location, they’re often known as “dead man systems.”

Blockchain for the distribution chain

Blockchain is a game-changer in logistics. Based on distinctive digitally signed blocks, they’re the perfect software to know the distribution stage of any given product. Thus, when a element or product enter or depart a warehouse or manufacturing facility, the system can observe their location and distribution part.

As in comparison with the normal system, these improvements present huge benefits for industrial shoppers in addition to ACCIONA’s staff. As a pioneering and innovating firm, it has carried out all these advances to enhance the effectivity of intralogistics operations.