At the I’mnovation Hub, we all the time have our eye on the improvement of new supplies, whether or not for the development of buildings or new gadgets. In that sense, nature is a fertile floor to attract inspiration for innovation. Proof of that is the beetle-inspired development materials we talked about not too long ago or the adhesive that mimics the skills of geckos. This time, the mastery is attributable to spiders, whose webs are one of nature’s elastomers.

You’ve in all probability heard of the proverbial power of spider webs. It is a versatile but extremely powerful materials. Without additional ado, we’ll clarify the motive for these qualities and what its latest functions are.

In this text, you can see out:

What are elastomers?

First of all, let’s clear up some doubts about this kind of materials. The time period elastomer is derived from “elastic” and “polymer.” There you have already got a pair of clues about their nature: they’re elastic polymers. Thus, these constructions are characterised by their stretching potential and skill to regain their pure form. A primary instance of an elastomer of plant origin can be rubber.

Natural elastomers, corresponding to these seen in rubber are inclined to soften with warmth and turn into brittle with chilly. Specific remedies are essential to make them actually efficient. For this motive, since the early twentieth century, artificial elastomers have been displacing pure elastomers. There are greater than twenty differing types of elastomers, together with latex, polyurethane, silicone, and neoprene. Today their functions are virtually infinite. Some of the most widespread are

- Tires

- Cable insulation

- Tubes

- Gloves

- Hoses

- Balloons

- Windshield wipers

- Rubber bands

- Conveyor belts

- Prosthetics

In addition to those on a regular basis functions, elastomers are opening the door to far more revolutionary functions. Let’s check out some of them.

The ultra-strong materials primarily based on spider net elastomers

As we’ve famous, people are removed from being the first to provide and use elastomers. One of the strongest elastomers in nature incorporates molecules with eight hydrogen bonds and is utilized by spiders to weave their traps. You have in all probability learn that spider webs are stronger than metal.

The Norwegian University of Science and Technology (NTNU) has checked out this kind of molecular construction to develop an ultra-strong materials.

Spider webs, particularly concentric rings, mix two qualities that don’t often go hand in hand: stiffness and toughness. Until now, in the case of industrial merchandise, the increased the stiffness, the decrease the toughness. This is as a result of the increased the stiffness, the decrease the power dissipation. An instance is glass, which is stiff however not exhausting.

Fortunately, researchers at the Norwegian college have mixed each traits in a brand new materials, which has a tough and softer half. The hydrogen-bonded construction is perfect for dissipating power, whereas the delicate half is made of a silicon-based polymer often known as PDMS.

The materials, which along with being ultra-strong, may be self-repairing, has varied functions. For instance, it could possibly be utilized in good clothes because of its means to withstand torsion.

Graphene spider webs

Just as elastomers are extraordinarily frequent in our day by day lives, there may be an equally ubiquitous materials in the subject of superior analysis. We are speaking, of course, about the ubiquitous graphene. One of the newest functions of this carbon-based materials takes benefit of the silk constructions of spider webs and the flexibility of PDMS, the polymer we noticed in the earlier case.

As reported in the scientific journal ACS Applied Materials & Interfaces, a Hong Kong University of Science and Technology staff has created a brand new sort of extremely versatile and delicate sensor with an E-GWF construction. This stands for “elastomer-filled graphene cloth” and is the key to expertise with nice potential.

The modern cloth, which consists of PDMS yarns with a graphene coating, is piezo-resistant. This signifies that, along with being versatile, it’s delicate to variations in the electrical subject, so it may be utilized in epidermal sensors and different gadgets in touch with human pores and skin.

An elastomer-based synthetic muscle

The creation of a cloth that behaves like human muscle mass, i.e., that contracts with excessive responsiveness to stimuli, has been the topic of a lot analysis. Fortunately, it appears that evidently elastomers have as soon as once more come to the rescue of scientists to take a vital step on this course.

This time it’s liquid crystal elastomers, often known as LCEs for brief. Researchers at the University of California have utilized an electrospinning course of to fabricate these artificial fibers that mimic human muscle.

By utilizing electrospinning, which applies {an electrical} discharge to the polymer to generate an especially skinny filament, the staff has succeeded in creating a cloth with excessive tensile power and excessive responsiveness to warmth or near-infrared mild.

This new instance of an elastomer may have thrilling functions in human muscle reconstructive surgical procedure or the improvement of robotic muscle methods.

Elastomers that behave like Batman’s cape

In case anybody hadn’t seen, Superman’s cape was purely decorative. For a cloth to permit something remotely resembling flight, it should supply some air resistance, as in the case of a chicken’s wing. There, if solely in phrases of realism, the system utilized by the bat-man was way more practical.

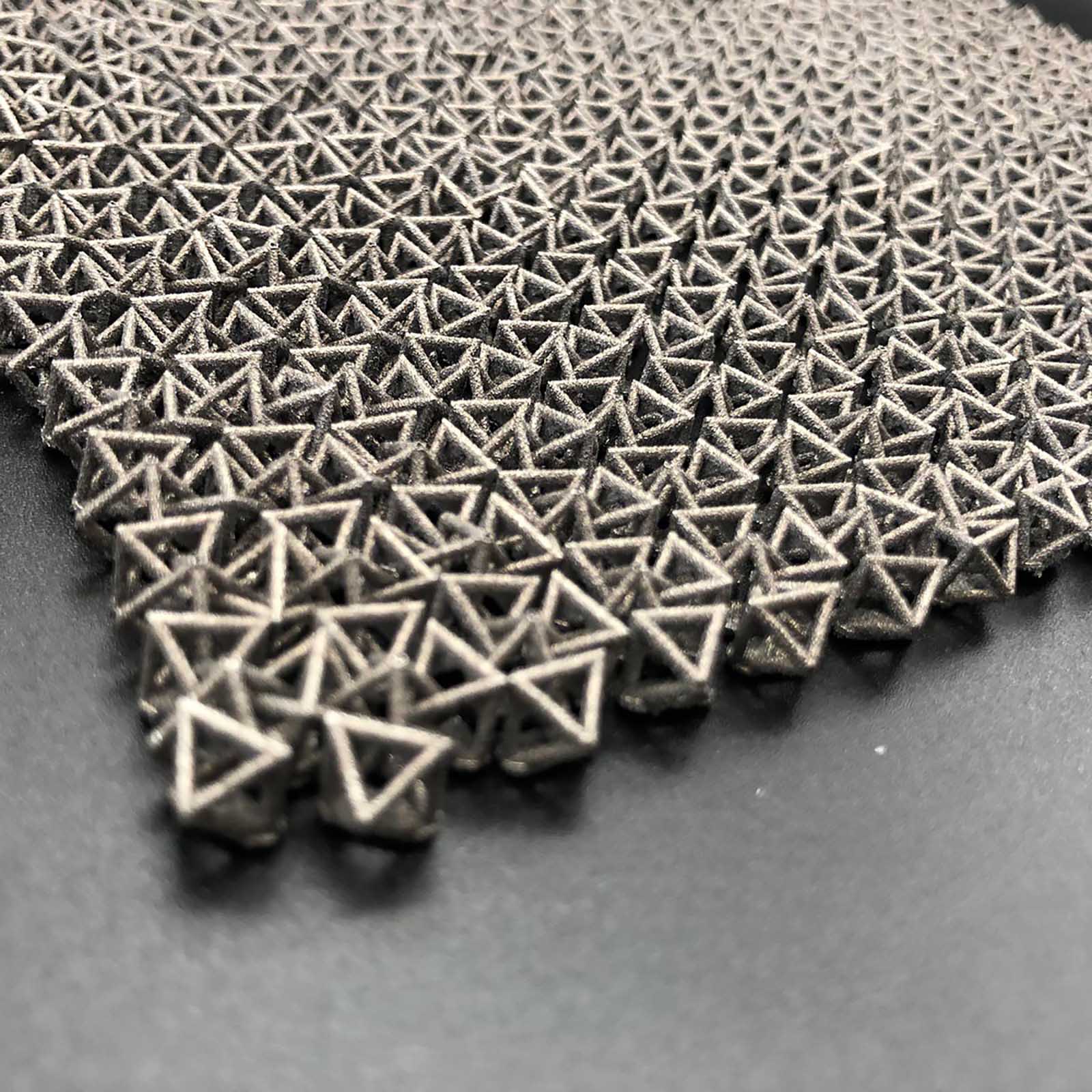

The new materials developed at the Caltech labs in the U.S. follows a precept much like that seen in Batman Begins, the place the hero turned his cape right into a inflexible floor to glide round Arkham.

The cloth developed at this heart related to the University of California consists of an octahedron-shaped polymer mesh obtained via 3D printing. This cloth, with a construction much like a series mail, turns into inflexible in the presence of warmth.

This is achieved using a layer of liquid crystal elastomers or LCE, the elastomer instance we noticed in the earlier case. When an electrical present is utilized to them, warmth is generated, which shrinks them and causes them to take on a preset form.

The modern construction may allow the manufacture of exoskeletons in the subject of biomedicine and even momentary shelters in the occasion of a catastrophe.

In addition to the examples of elastomers talked about above, if you wish to study extra about supplies impressed by crops, birds, and bugs, you possibly can check out this text on biomimetics.

Sources: Engineering Plastics, Scitech Daily, Nanowerk, Caltech, ACS, https://techxplore.com/information/2021-09-artificial-fiber-spun-liquid-crystal.html