In a hangar at the University of Edinburgh, a triangular metal contraption sits beside a large tank of water. Inside the tank, a technician in a yellow dinghy adjusts tools in order that the triangled construction will be hoisted into the water to see the way it offers with simulated waves and currents. One day quickly, a platform 50 instances as massive might float in the deep waters of the North Sea, buoying up a large wind turbine to harvest the regular, sturdy breezes there. About an hour’s trip up the coast, full-scale 3,000-tonne behemoths already float in Aberdeen Bay, capturing sufficient wind vitality to electrify practically 35,000 Scottish households.

The prototype at the

FloWave facility—certainly one of 10 new floating wind-power designs being examined right here—is progressing quick, says Tom Davey, who oversees testing. “Everything you see here has been manufactured and put in the water in the last couple months.”

There’s good motive for this hustle: The United Kingdom needs to add 34 gigawatts of offshore wind energy by 2030, en route to decarbonizing its grid by 2035. But the shallow waters east of London are already filled with wind generators. Scotland’s deeper waters are due to this fact the U.Ok.’s subsequent frontier. Auctions have put aside parcels for 27 floating wind farms, with a mixed capability exceeding 24 GW.

This scale mannequin of a floating wind-turbine platform is certainly one of 10 new designs being examined at the University of Edinburgh’s FloWave facility.Peter Fairley

This rush to deep water is a world phenomenon. To arrest the accelerating tempo of a altering local weather, the world wants much more clear vitality to electrify heating, transportation, and trade and to displace fossil-fuel technology. Offshore wind energy is already taking part in a key function on this transition. But the steadiest, strongest wind blows over deep water—effectively past the 60- to 70-meter restrict for the mounted foundations that anchor conventional wind generators to the ocean ground. And in lots of locations, similar to North America’s deep Pacific coast, the strongest and steadiest wind blows in the night, which might completely complement photo voltaic vitality’s daytime peaks.

Hence the push for wind platforms that float. The Biden administration has referred to as for 15 GW of floating offshore wind capability in the United States by 2035, and up to date analysis means that the U.S. Pacific coast may help 100 GW extra by midcentury. Ireland, South Korea, and Taiwan are amongst the different nations with daring floating wind ambitions.

The query is how to scale up the know-how to gigawatt scale. This international debate is pitting innovation towards threat.

On the innovation finish are folks like Davey and the FloWave workforce, who’ve already superior a number of floating wind gadgets to sea trials. One FloWave-tested platform, engineered by Copenhagen-based Stiesdal Offshore, was just lately chosen for a 100-megawatt wind farm to be constructed off Scotland’s northern tip in 2025.

Kincardine Offshore Wind Farm challengePrinciple Power

Established tech firms, nonetheless, argue that their extra conservative designs are prepared to go right now, and at greater scale. What the trade actually wants to drive down prices, they are saying, is economies of scale. “In our view, this is purely a deployment question,” says Aaron Smith, chief business officer for the floating wind-tech developer Principle Power, primarily based in Emeryville, Calif., whose platforms help the 190-meter-high, 9.5-MW generators working in Aberdeen Bay.

If governments present constant, long-term subsidies, trade standardization and mass manufacturing will ship the gigawatts, Smith says. “We have the technology. We’re just angling for the right market conditions to deploy that at scale.”

What are the benefits of floating wind energy?

To totally perceive what builders are up towards, it helps to understand how laborious it’s to deploy any sort of wind energy at sea. The 15-MW generators being ordered right now for tomorrow’s offshore wind farms weigh roughly 1,000 tonnes. The foundations of conventional offshore wind generators are additionally large metal or concrete constructions which have to be embedded in the ocean ground. And putting in a turbine atop a tower that’s twice as tall as the Statue of Liberty requires devoted and dear vessels, that are in

brief provide worldwide.

You can do with out such vessels through the use of a floating platform. The tools will be totally assembled on shore after which towed to the website. But having a platform that floats compounds the problem of supporting the towering turbine.

To stabilize the first floating wind farm, accomplished in 2017 about 50 kilometers northeast of the Aberdeen challenge, Norwegian vitality large Equinor used a metal column that extends 78 meters into the water. This dense mass, referred to as a spar platform, works like the keel of a ship. Equinor used the identical design for an 88-MW, 11-turbine array—the world’s largest, although most likely not for lengthy—accomplished this 12 months in Norway. At that challenge, cables switch the electrical energy to oil and fuel platforms, quite than delivering the energy again to shore.

Equinor constructed floating wind farms in Scotland and Norway. The generators and platforms will be assembled on shore after which towed out to sea.Jan Arne Wold/Woldcam/Equinor

Equinor constructed floating wind farms in Scotland and Norway. The generators and platforms will be assembled on shore after which towed out to sea.Jan Arne Wold/Woldcam/Equinor

Ole Jørgen Bratland/Equinor

Ole Jørgen Bratland/Equinor

For its subsequent floating wind initiatives, Equinor plans to use the extra conservative semisubmersible design, a know-how perfected for oil and fuel platforms. Semisubmersibles don’t go deep the manner spar platforms do; as a substitute, they obtain stability by extending their buoyancy horizontally.

Principle Power’s WindFloat is a three-sided semisubmersible platform that’s roughly 70 meters on a facet. A concrete sq. variant from France’s BW Ideol is 35 to 55 meters on a facet.

Chains and anchors in the seabed stop these platforms from spinning or drifting, which is essential for minimizing the actions that will flex and fatigue the generators’ energy cables. Some platforms, similar to WindFloat, shift ballast round to dampen wave motion or to preserve the rotor perpendicular to the wind in order to maximize vitality seize. WindFloat strikes the water ballast with pumps that run for about 20 minutes a day. “You’re naturally going to be heeling out of the wind, just like with a sailboat. We’re shifting the water balance to compensate,” explains Smith.

Principle Power then marries typical wind generators to the firm’s floating platforms, making small however very important tweaks to the turbine’s management system to compensate for the variations between mounted and floating circumstances. For instance, if a floating platform begins to tip due to sturdy waves, a management system designed for a hard and fast basis might interpret the motion as a change in wind pace after which pitch the blades in response. That correction may as a substitute amplify the rocking movement. WindFloat’s turbine controls are tuned to stop such harmful suggestions.

Until 4 or 5 years in the past, floating wind builders had to kind out such points on their very own, as a result of most turbine producers weren’t focused on working with them. But now that builders are searching for dozens of generators for gigawatt-scale floating initiatives, turbine producers are lastly devoting engineering sources to the trigger.

Thomas Choisnet, till just lately chief know-how officer of BW Ideol, says the present technology of 15-MW generators developed for fixed-foundation wind farms even have specs for floating. “They are making sure that everything works in this moving environment,” he says. Floating initiatives thus profit from the a long time of design optimization and manufacturing scale that went into constructing right now’s typical offshore wind installations.

Conventional approaches take the lead

Beyond the technological benefits of utilizing a tried-and-true method, there’s a monetary upside, Smith says. Floating wind builders should persuade risk-averse bankers and insurers to again their initiatives, and it helps to find a way to level to your challenge’s use of established know-how. In years previous, offshore wind buyers who backed modern however flawed designs suffered enormous losses.

Gigawatt-scale offshore installations additionally require large private and non-private investments in ports and provide chains. Consider the

960-MW Buchan wind farm that Ideol is creating for the Scottish North Sea. Because the challenge features a seasoned know-how supplier, it’s transferring sooner than most. The consortium has already secured connections to the grid, and Ideol has secured 34 hectares east of Inverness to manufacture its platforms.

The homeowners of the mothballed

Ardersier Port, which as soon as serviced oil and fuel platforms, plan to work with Ideol to rework the port right into a regional hub that can ship floating wind platforms to initiatives throughout the North Sea. To produce the steel-reinforced concrete for Ideol’s platforms, Ardersier will get a brand new concrete plant, an oil-rig decommissioning facility, and the U.Ok.’s first new steelworks in half a century, to recycle the rigs’ metal. The metal mill, says Ideol, will likely be certainly one of the world’s first to substitute metallurgical coal with renewable electrical energy and hydrogen.

Building superstable platforms like Ideol’s and Principle Power’s to accommodate typical generators is pricey. According to the consulting agency

BloombergNEF, latest floating initiatives value up to US $10 million per megawatt. The ensuing energy is roughly 3 times as costly as technology from fixed-bottom offshore wind. And these excessive prices are hindering builders’ skill to clinch long-term power-supply contracts with utilities. In June, vitality consultancy 4C Offshore reduce its international floating wind-power projection for 2030 by practically 1 / 4 in contrast with its projection from a 12 months earlier.

France’s BW Ideol makes use of a sq. of concrete for its floating platform [left and at top]. Like Principle Power’s metal triangular platform [right], its horizontal traces lengthen its buoyancy, holding it steady.Left: V. Joncheray/BW Ideol; Right: Principle Power

France’s BW Ideol makes use of a sq. of concrete for its floating platform [left and at top]. Like Principle Power’s metal triangular platform [right], its horizontal traces lengthen its buoyancy, holding it steady.Left: V. Joncheray/BW Ideol; Right: Principle Power

At the Floating Offshore Wind Turbines convention held final May, a number of builders referred to as on main turbine producers, similar to Vestas and General Electric, to adapt their {hardware} to assist scale back the value of floating wind. For instance, if generators may take care of extra movement, then floating platforms might be smaller, and thus inexpensive, says

Cédric Le Bousse, director for marine renewable vitality for the French utility Électricité de France, which just lately put in a three-turbine floating wind demonstration close to Marseille. As it’s, he says, floating platforms should be “over-dimensioned” to obtain the strict limits on actions set by the turbine producers.

The promise of latest designs

Meanwhile, floating wind’s mold-breakers are providing an ever-expanding range of know-how choices. At least 80 designs for platforms or built-in platform-turbines now vie for the floating wind market.

For starters, there are dozens of platform designs. There are semisubmersibles that seat the turbine towards the heart of the construction, similar to Stiesdal’s tetrahedral

TetraSub. That geometry distributes the rotor’s weight and torquing forces and reduces the platform’s weight and thus its value. There’s a 40,000-tonne spar platform that replaces the metal column with a less expensive, 285-meter-long column of concrete.

More radical floating wind-power designs flout decades-old engineering assumptions. Many of those assumptions make much less sense far offshore, says

Klaus Ulrich Drechsel, an offshore-energy engineering supervisor for the German utility EnBW. “It’s important to not only try to overcome the disadvantages but also to take advantage of the potential benefits of floating.”

Myriad Wind Energy Systems describes its 12-rotor wind turbine as a “wind farm on a stick.”Myriad Wind Energy Systems

Myriad Wind Energy Systems describes its 12-rotor wind turbine as a “wind farm on a stick.”Myriad Wind Energy Systems

For instance, some floating turbine configurations permit the rotor to face downwind. Turbine makers had lengthy averted doing that as a result of it’s noisy, as the blades should move by the wind’s “shadow” behind the tower. But far offshore, the ensuing

thump-thump-thump is unlikely to offend anybody. And the wind itself can then orient the rotor, eliminating the want for motors and gears that preserve typical generators going through into the wind.

Another concept is to add extra rotors to a single tower. Multirotor generators can improve manufacturing by forcing extra air to stream by the rotors. The rotors’ counterrotation, in the meantime, neutralizes the torquing power that tilts single-rotor floaters to one facet and strains turbine towers.

Big company gamers are taking on the multirotor and downwind designs. Plenitude, a subsidiary of the Italian oil and fuel producer Eni, has

purchased into EnerOcean, a Spanish agency that validated its 12-MW twin-rotor design at FloWave. Chinese turbine large Mingyang Smart Energy Group is manufacturing a floater with twin 8.3-MW rotors, set for set up this 12 months off Macau. EnBW is cofunding that demonstration, in change for unique rights to deploy the design in Europe.

The trio of business Ph.D.s behind Scottish startup

Myriad Wind Energy Systems determine two rotors can’t seize the full advantages of a number of rotors. Their 90-meter-tall array has 12 rotors. “We’re seeing it as kind of a ‘wind farm on a stick,’” says Paul Pirrie, Myriad’s CTO.

Myriad makes use of a pivoting tree construction to help the rotors. The body is modular for simpler transport. Integrated tracks and lifts facilitate meeting, with the turbine mills and rotors delivered to the base and raised into place. Any defective tools, which in any other case can be a logistical nightmare to restore or substitute out at sea, can return to the tower’s backside through the tracks and lifts, with the substitute half hoisted aloft through the identical route.

Myriad hopes to have a demonstrator put in on land in 2025. But the firm is already going through competitors from Oslo startup Wind Catching Systems, whose 126-rotor floating design is in prototype improvement with assist from General Motors.

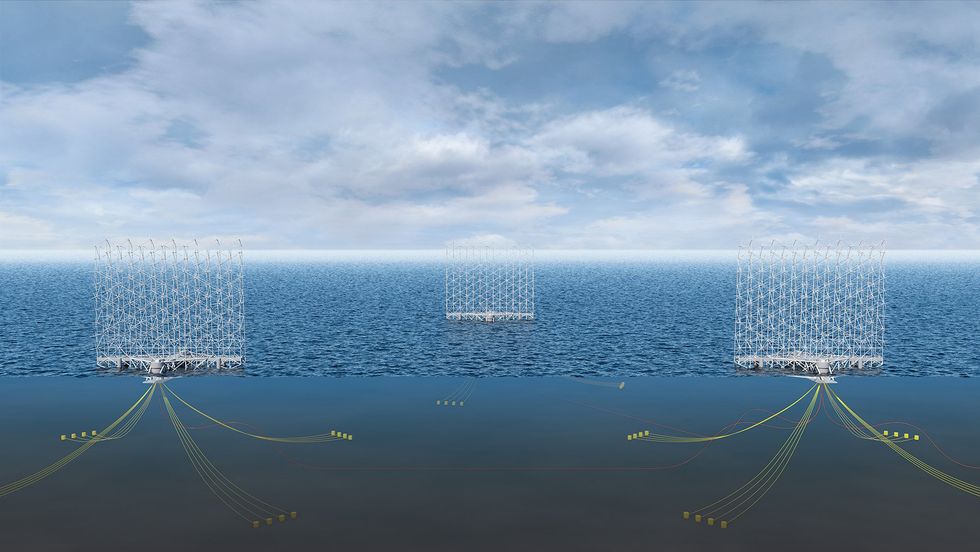

Wind Catching Systems’s 126-rotor design can be tethered to the ocean ground. Some floating wind designs name for a very tetherless platform.Wind Catching Systems

Wind Catching Systems’s 126-rotor design can be tethered to the ocean ground. Some floating wind designs name for a very tetherless platform.Wind Catching Systems

Sustained authorities help is essential

Ultimately, floating wind energy may grow to be fully untethered. Several groups worldwide are actually engaged on wind

ships, an idea first recommended by the U.S. wind-energy pioneer William Heronemus in 1972. He envisioned a tetherless, self-propelled floating platform that will seize wind energy, use it to generate hydrogen, and retailer that gasoline for supply to shore. (Heronemus additionally launched the University of Massachusetts’ wind-engineering program, coaching the engineers who launched the U.S. wind-power trade.)

Autonomous wind ships reduce out the energy cables and mooring chains utilized by floating offshore wind platforms. Concepts like the UMass workforce’s Wind Trawler, a contemporary model of Heronemus’s wind ship, “are not depth limited at all and so have a potentially enormous capture area,” says

James Manwell, an engineering professor at UMass Amherst.

Eliminating energy cables and mooring chains may additionally assuage a few of the issues over offshore wind’s potential impact on fisheries and wildlife. For instance, fishing is mostly banned inside wind farms to keep away from entanglement of fishing gear. Such fishing-free zones have a tendency to improve fisheries, offering a refuge by which fish develop bigger and reproduce. Nevertheless, fishing pursuits usually oppose any limits to their freedom to fish, arguing that restricted areas power them to journey additional. Citing such issues, Oregon’s governor just lately referred to as for a

pause in offshore wind preparations, regardless that generators floating off the Pacific coast are nonetheless years away.

In the close to time period, the floating wind trade faces a extra intrinsic, logistical downside. Namely, builders want ports to begin gearing up to construct and launch their large wind machines.

Scottish Renewables, a regional trade group, says that the U.Ok. “urgently” wants to rework no less than three ports into industrial hubs to ensure that the nation to meet its 2030 vitality and emissions targets. And but the trade hasn’t settled on which turbine and platform designs are greatest, and so ports have no idea how to gear up.

Iain Sinclair [left] and Rory Gunn are with the Global Energy Group, which is remodeling Scotland’s Port of Nigg right into a wind-power hub. Peter Fairley

Iain Sinclair [left] and Rory Gunn are with the Global Energy Group, which is remodeling Scotland’s Port of Nigg right into a wind-power hub. Peter Fairley

“The variables make for an absolute minefield,” says

Iain Sinclair, government director for renewables and vitality transition for the Edinburgh-based Global Energy Group. Sinclair’s firm owns three Scottish ports, together with the Port of Nigg northeast of Inverness, which has been recognized as certainly one of the most promising locations for floating wind energy.

Back in the day, Nigg constructed about 40 % of the North Sea’s oil and fuel platforms. At the port’s peak in the Nineteen Seventies and Eighties, 4,000 folks labored there, and petroleum fumes crammed the air. Today, you’re extra possible to odor distillery vapors wafting over the harbor—what locals name the “angels’ share” of the Highland’s fashionable single malts. Nigg’s oil terminal is shuttered, and drilling platforms go to sometimes. But there’s loads of bustle now, thanks to investments by Global Energy Group which have turned Nigg right into a staging level for offshore wind development. When

IEEE Spectrum visited, cranes have been lifting huge towers, nacelles, and blades onto an set up vessel, destined for a fixed-foundation wind farm.

Sinclair is betting that constructing, deploying, and sustaining floating wind farms will in the end dwarf the final century’s oil and fuel growth. And it may occur quick: An unbiased

2021 report predicted that floating offshore wind would contribute £1.5-billion to Scotland’s financial system by 2027 with solely modest port upgrades, and up to triple that quantity with extra strategic investments.

To decide the place to focus Nigg’s upgrades, Sinclair and his workforce have assessed 57 floating wind designs and zeroed in on a half-dozen of the most promising. They’ve mapped these designs onto Nigg’s current and potential capabilities, similar to manufacturing tubular metal, assembling elements in the port’s 36,000 sq. meters of coated fabrication house, and pairing generators to platforms alongside the harbor’s 1.2-km-long quayside.

What the floating wind trade actually wants now, says Sinclair, is sustained authorities help. At Nigg, meaning greater than the U.Ok. authorities’s £160 million for floating offshore wind manufacturing introduced in March, which Scottish Renewables says “falls woefully short.” It additionally means a plan to develop Scotland’s ports, which may value £4 billion. The identical issues are being voiced by floating wind proponents in the United States, France, Germany, and different nations, as they push for their very own infrastructure upgrades.

Henry Jeffrey, certainly one of Tom Davey’s colleagues at the University of Edinburgh, is a transplant from offshore oil and fuel engineering who now codirects the U.Ok.’s Supergen Offshore Renewable Energy R&D effort. He agrees that governments want to step up. Jeffrey says politicians ask him all the time when floating offshore wind know-how will likely be aggressive.

“I say, ‘Well, it’s directly proportional to your political will. It’s up to you to make it happen,’” Jeffrey says. The know-how is “as close and credible as government wants it to be.”

From Your Site Articles

Related Articles Around the Web