My dwelling of Port Townsend in Washington is a neighborhood filled with arty varieties and makers. Calls to take part in native cultural actions should not unusual, however after I noticed one for a pinhole-camera images contest it caught my eye. I’d performed with pinhole cameras a few years in the past, and I questioned if the electrotech abilities I’d accrued since then could possibly be used to enhance upon the normal pinhole digital camera, whereas retaining its distinctive traits. Could I make a digital pinhole digital camera?

Optically talking, pinholes have some compelling traits that lenses can’t match. For one, a pinhole digital camera has an successfully infinite depth of area: all the things in its area of view is in focus, no matter how close to or far any object is. And there aren’t any distortions, equivalent to

chromatic aberration, which might be produced by lenses. Recent years have seen a rise in curiosity in pinhole images, with a wide range of cameras being bought commercially and worldwide images occasions.

On the draw back, each off-the-shelf and DIY pinhole cameras use movie or photographic paper. The value of shopping for and growing movie rapidly provides up, and naturally there’s an extended delay between taking a photograph and seeing the outcomes. Perhaps most importantly, taking images with a film-based pinhole digital camera requires lengthy publicity instances—usually a number of seconds even in brilliant daylight—rising the possibility of a shot being ruined by undesirable movement.

The body and pinhole lens attachments are constituted of laser-cut items of wooden. These maintain the microcontroller board [center], picture sensor, and the microswitch that acts as a shutter management [top center].James Provost

My hunch was that utilizing a digital sensor would remedy each these issues. I had a US $10

ESP32-Cam board left over from a earlier undertaking that I spotted could be good for this endeavor. The board integrates the favored Wi-Fi–enabled ESP32 microcontroller with a microSD card socket, an indicator LED, and an interface for numerous low-cost picture sensors. I used an OV2460 digital camera module, which may assist a most decision of 1,600 by 1,200 pixels when used with the ESP32-CAM. I eliminated the OV2460’s lens to reveal the picture sensor.

I wired up a microswitch to one of many board’s general-purpose enter/output pins and

wrote some firmware to make use of the swap as a shutter management and save photos to the microSD card. I additionally programmed the indictor LED to blink out some error codes in case one thing went improper, equivalent to making an attempt to write down to a full microSD card. Writing this glue code didn’t take lengthy, due to the big variety of software program libraries obtainable for the ESP32-CAM.

I made a picket case to carry the sensor, ESP32-CAM board, and the shutter swap utilizing my

Glowforge laser cutter. The vital pinhole meeting could be indifferent, permitting me to regulate the focal size—and therefore the sector of view of the digital camera—by swapping out completely different assemblies. This brings the pliability of removable lenses to pinhole images, one other good bonus!

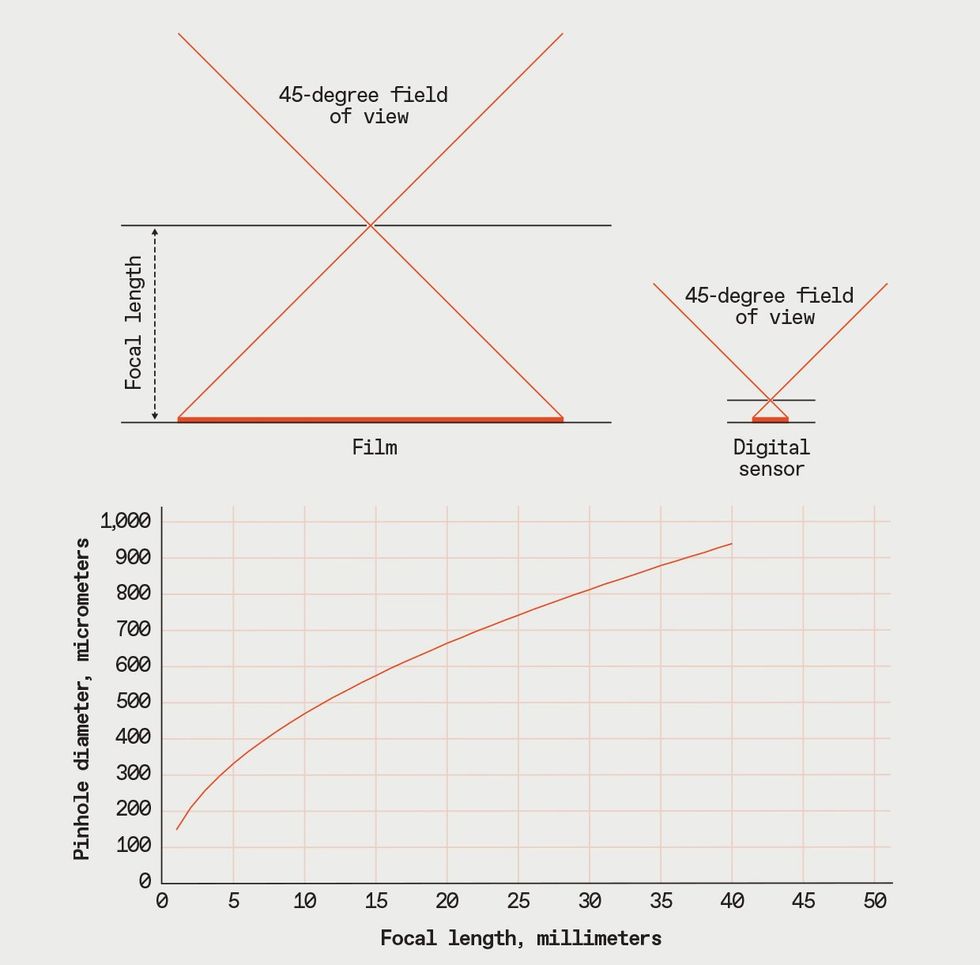

However, nothing comes totally free. Pinholes do fluctuate in dimension, and the trade-off for all these digital benefits is that it’s important to fabricate a digital camera pinhole with a smaller diameter than you may get away with in a conventional pinhole digital camera. This is as a result of the sensor is way smaller than a body of movie: 4 millimeters vast for the sensor versus, say, 35 or 120 mm for movie. Consequently, to make sure the entire picture created by the pinhole falls onto the sensor’s floor, the sensor have to be a lot nearer to the pinhole than with movie. When you calculate the optics wanted for that association, the result’s a smaller gap.

If I used to be mass-producing this digital camera, the go-to course of could be chemical etching. Once you dial in all of the parameters you’ll be able to exactly make very small holes all day lengthy. But the effort and time concerned in organising an etching course of meant I needed to seek out one other means.

My first answer was get a skinny piece of brass and make a dent in it with a middle punch. Then I sanded off the brass from the opposite aspect till I simply broke by means of to the dent. This made a pleasant tiny little gap, but it surely was numerous work, and I knew I’d need a couple of pinholes available as I examined the digital camera.

Not all pinholes are the identical. Traditional pinhole cameras have comparatively lengthy focal lengths due to the scale of a body of movie, permitting for bigger and easier-to-make pinholes. Because digital sensors are a lot smaller, a shorter focal size is required, demanding in flip a a lot smaller pinhole.James Provost

Not all pinholes are the identical. Traditional pinhole cameras have comparatively lengthy focal lengths due to the scale of a body of movie, permitting for bigger and easier-to-make pinholes. Because digital sensors are a lot smaller, a shorter focal size is required, demanding in flip a a lot smaller pinhole.James Provost

So I went again to fundamentals and tried stretching some aluminum foil and piercing it with a needle. Normally, this could end in a gap that’s far too massive. However, I found that if I put the foil down on the plastic floor of my work bench, and pressed the needle gently into the foil, the plastic would enable simply the very tip of the needle to penetrate the foil. Although not tremendously dependable, this technique lets me make numerous pinholes rapidly and test them to seek out those with the best diameter.

Then it was time to check out the digital camera, so I took it out to a neighborhood lighthouse and connected a battery. The sensitivity of the picture sensor implies that the publicity time required is just a fraction of second, and I used to be in a position to obtain my images from the microSD card and test them proper there on the shore. Yet the images retained the luminous look that’s attribute of conventional pinhole images. Success!

An apparent enchancment could be to coat the within of the interchangeable optical assemblies with some matte black materials, as inside reflections add some fuzziness to my images. Another could be so as to add an LCD display screen in order that you may view precisely what the digital camera is seeing in actual time—the ESP32 controller has greater than sufficient spare compute energy to drive a small show.

Meanwhile, I’m nonetheless ready to listen to how I did in that images contest!

From Your Site Articles

Related Articles Around the Web